Company Profile

Company Profile

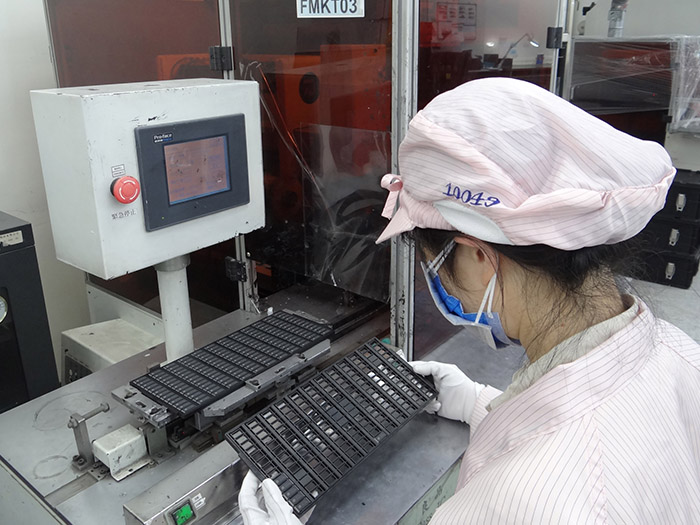

“Probe Test System Corp.(PTS) offers fully integrated semiconductor backend manufacturing services. PTS is partnered with leading industry companies, such as: Winbond, MediaTek, Novatek, Nuvoton, Macronix, AAT…etc. Presently, we have three factories in Hsinchu, Zhunan and Toufen. In the course of our development, we hope to work with like-minded talent to join us in sharing our company’s progress and growth.“

Core Values

All colleagues takes “service” as the prime objective, they realize what supports PTS forward are the “customers”!

Pride

enthusiastic, dynamic, customer-oriented.

Technique

a pioneer in the pursuit of advanced technology.

Service

to serve the customer is always first.

Mission

PTS has industry-standard core technologies, being an advanced supplier of module testing, CP testing, and T/R with cost-effective and added-value. By providing customers with the most cost-effective services, we aim to be long-term trusted partners.

Quality Policy

Honesty; Value-added Service; Innovation – to ensure product quality and to reach customers on time of the mission entrusted to meet customer needs.

Occupational Safety and Health Policy

- Safe and hygienic working environment, eliminating the generation of hazardous factors.

- Cultivate a quality culture of safety and hygiene, and prevent occupational injuries and diseases.

- Reduce the risk of occupational hazards and comply with legal requirements.

- Worker participation and consultation, continuous improvement management system.

Environmental Policy

- Comply with the law, pollution prevention.

- Conserve energy, recycling resources.

- Continual improvement of quality and service.

History

| 2000 | Jan | Baking/packaging line and equipment set up. |

| 2000 | Feb | Trial production completed; passed Huabang quality certification. |

| 2001 | Feb | Introduced rubbing/stamping machine; trial production completed in the same month. |

| 2001 | Mar | Passed the quality certification of Huabang and many customers. |

| Formal mass production of rubbing/stamping products. | ||

| 2001 | Oct | Formally passed the ISO9001-2000 certification. |

| 2002 | Jan | Formally passed the ISO9001-2000 certification. |

| 2002 | Sep | Increased the tape and reel packaging product line. |

| 2002 | Oct | Increased laser stamping product line. |

| 2003 | Oct | Increased laser stamping product line. |

| 2004 | Expanded Tape & Reel and Lead Scan production capacity. | |

| 2005 | Expanded Tape & Reel and Lead Scan production capacity. | |

| 2006 | Prepared for Auto Bench Test, T/R & L/S production capacity. | |

| 2007 | Expanded Auto Bench Test production capacity. | |

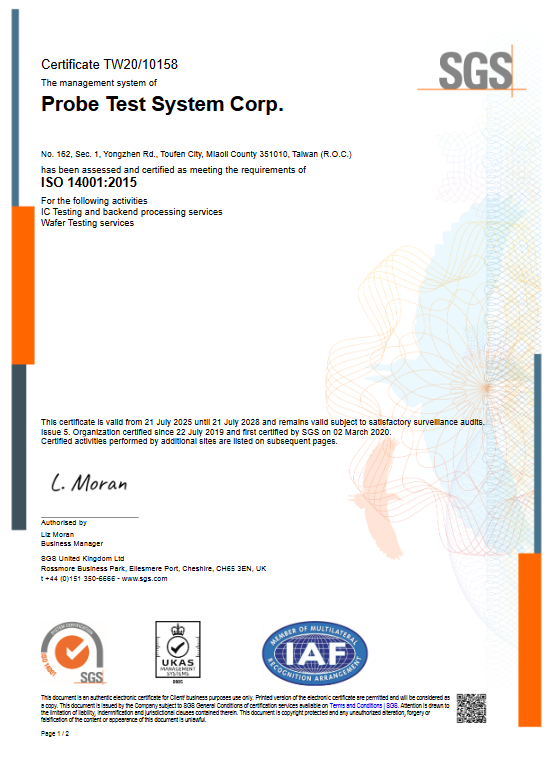

| 2008 | Jul | Formally passed ISO-14001 2000 certification. |

| 2009 | Oct | Formally passed ISO-14001 2000 certification. |

| 2010 | Increased the number of T/R machines with vibration disk design, suitable for thin and light ICs. | |

| 2011 | Expanded T/R & L/S production capacity to 100KK/month and continued to grow steadily. | |

| 2012 | Expanded production capacity of T/R machine (SRM) for vibration disk design. | |

| 2014 | Expanded Auto Bench Test & T/R production capacity. | |

| 2015 | Continuous expansion of Auto Bench Test machine and introduction of Hung King machine and low temperature machine. | |

| 2016 | Feb | Obtained the bonded factory license (SLT). Increased Auto Bench Test (-40C~120C) clean room. |

| Q3 | CP product line established & CP clean room added. | |

| 2017 | Q4 | CP production capacity increased and moved to Zhunan factory. |

| 2018 | Set up Auto Bench Test machine. | |

| 2019 | Continuously expand production capacity of each product line (CP, Auto Bench Test, Marking, T/R & L/S). | |

| 2020 | Establishment of Toufen Plant (Auto Bench Test). | |

| 2021 | T/R production capacity of 150KK/month, Remarking production capacity of 12KK/month. | |

| 2022 | Q1 | CP Plant completed the expansion of the clean room plant with a total area of 610 ping. |

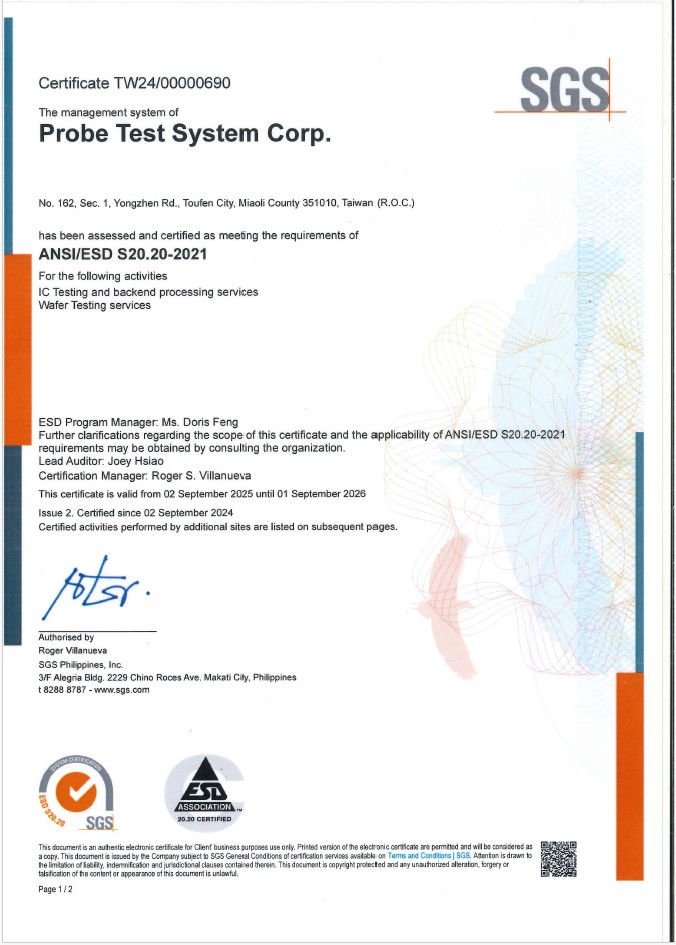

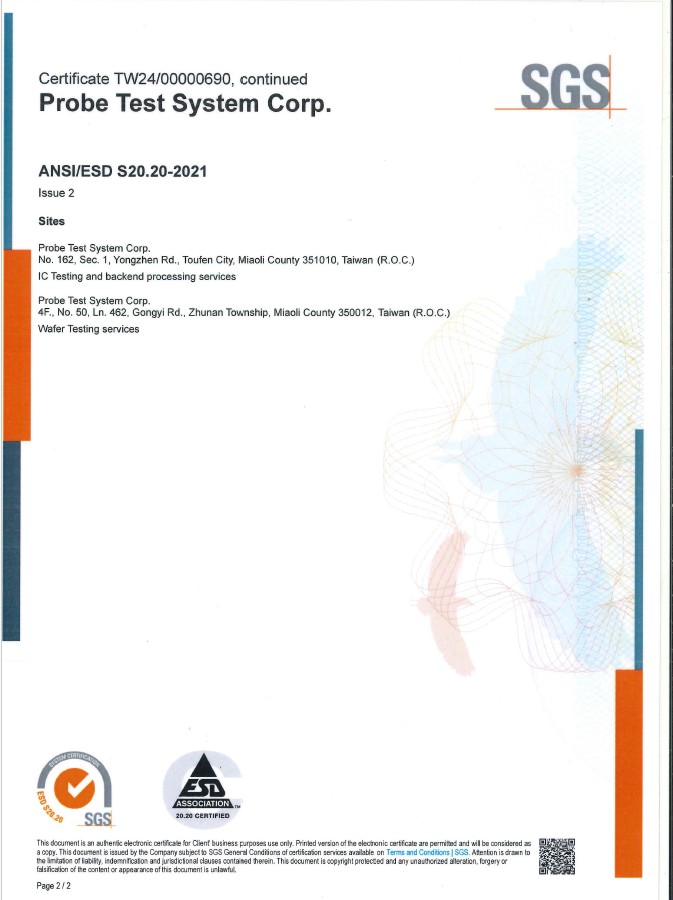

| 2023 | Q3 | Hsinchu, Zhunan, and Toufen plants obtain ANSI/ESD S20.20-2021 certification. |

| 2024 | Q1 | Headquarter moved to Toufen, successfully completed the consolidation of the two plants, And fully expanded the production capacity of each product line. |

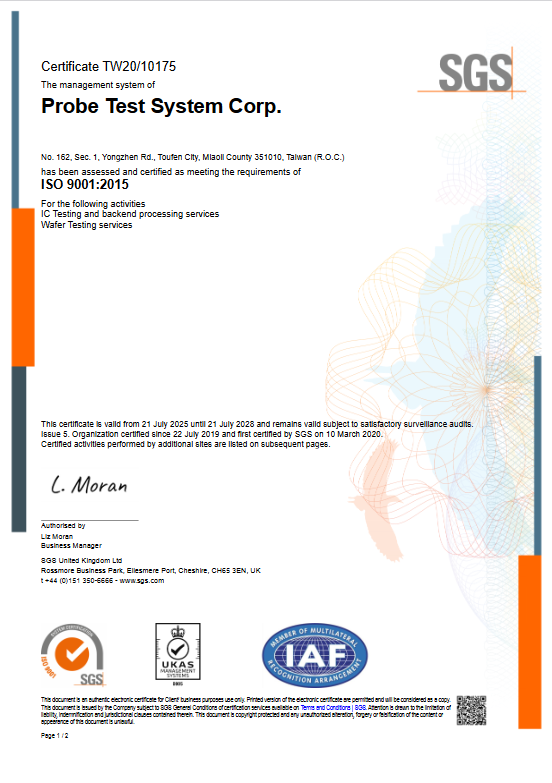

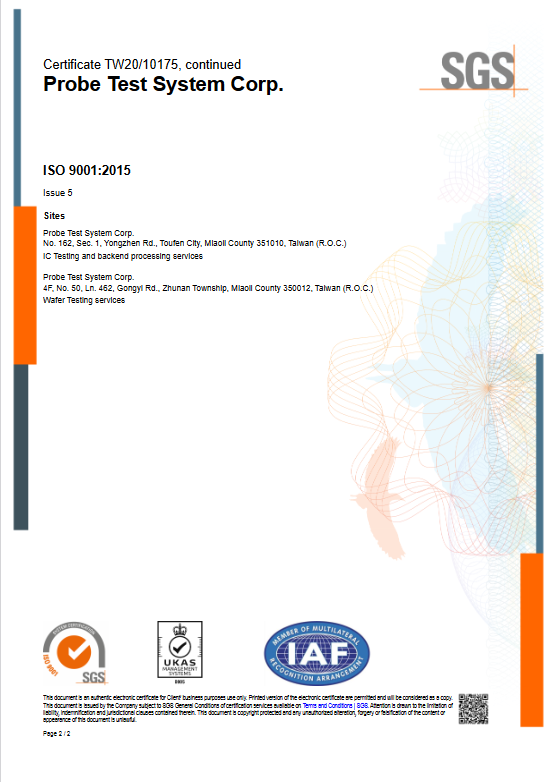

Quality certification

ISO 14001

ISO 9001

ANSI/ESD S20.20-2021